Quarrying and mining fire suppression systems

The global mining and quarrying industries pose some of the most demanding conditions for mobile plant. Long work schedules mean machines are usually in use 24 hours a day, seven days a week. Inaccessible sites with harsh climates, altitude challenges, and extreme temperatures put additional stress on machines and increase the risk of equipment fire.

Reliable mining fire suppression systems not only protect high-value equipment, but can also buy operators valuable time and allow a safe space from elevated cabs. When combined with dependable and highly responsive service and support, quarry and mining fire suppression systems help minimise downtime and maximise production levels.

Who uses our mining fire suppression systems?

-

Super-fast fire detection

Our mining fire suppression systems use infra-red fire detection technology, minimising damage to the machine.

-

Robust mining fire suppression systems

Robust mining fire suppression systemsEvery one of our systems is designed and tested to extreme temperatures, shock, and vibration.

-

Global specialist

We work with mining and quarrying operators in over 50 countries, in all conditions.

Why protect quarry and mining machines?

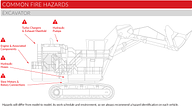

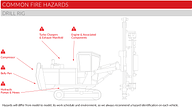

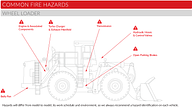

Large amounts of hydraulic oil and diesel, coupled with superheated components such as turbochargers and exhaust manifolds, make mobile plant a common cause of fire in mining and quarrying.

In underground mining, confined spaces and reduced exit routes can lead to catastrophic consequences in the event of a fire. One of the main concerns of a fire in underground mining is the generation of highly toxic gases and combustion products, which can run through the entire ventilation system of the mine.

Want us to give you a call?

Request a CallbackOur solution: mining fire suppression systems

At Ardent, we understand the consequences of equipment such as excavators and dump trucks being at standstill. We work with mining and quarrying operators around the world to ensure that their production-critical equipment is protected against the risk of fire 24/7. Whatever the scale of operations, we install, service and maintain reliable quarry and mining fire suppression systems to any fleet size.

We have years of experience designing quarry and mining fire suppression systems, providing solutions for equipment in both surface and underground construction. We’re used to working on inaccessible sites, and we know how to deal with fires in confined spaces - our systems are tailored for installation to compact underground machines.

The Ardent mobile plant fire suppression system is designed and tested to withstand the harsh mining conditions. We test our systems to the highest global standards for shock and vibration, and use a combination of fire detection technologies to ensure quick fire detection and system activation. Our infra-red detectors can detect a fire in less than three seconds - crucial when working with machines that carry vast amounts of fuel.

Fires on fixed equipment such as electrical cabinets, generators, and transformers can also result in downtime and costly repairs. Our electrical equipment fire suppression systems provide cost-effective and reliable protection, and the same level of service and support as our mobile plant systems.

Learn more about mining fire suppression systems

Read MoreService and support for quarry and mining fire suppression systems

At Ardent, we understand the impact of machine downtime on operations and productivity. That's why it’s not only our mining fire suppression systems that are always ready to react to fire, but our dedicated team is equally ready to respond to callouts within a matter of hours. Our systems are powered by a team who listens, understands quarry and mining company’s needs, and fits seamlessly into operations to provide the highest service standards in the industry.

Some mining and quarrying equipment we protect:

- Excavators

- Dump trucks

- Dozers

- Graders

- Drill rigs

- Loaders

- Crushers

- Screeners

- Electrical cabinets