Fixed fire suppression systems for static equipment

Fixed equipment isn't subject to the same challenging conditions as mobile plant, which are at greater risk of damage due to shock, vibration, and temperature changes. However, for small, fixed equipment such as electrical panels, fire risks are still present - and a pneumatic fixed fire suppression system is a highly cost-effective and fit-for-purpose solution to protect them.

Our fixed fire suppression systems are designed to offer reliable, cost-effective, and low-maintenance solutions for the protection for essential static equipment such as electrical panels and transformer cabinets. These systems are effective for small volumes that are well-sealed. They can flood a volume within approximately 0.5-metre radius from the tubing burst point, covering a small void effectively.

Why install a fixed fire suppression system?

Installing a fixed or transformer system offers a range of crucial benefits for businesses. By detecting and controlling fires early, these systems are designed to minimise downtime and production losses, while also protecting assets and your premises.

How our fixed fire suppression systems work

1. High temperatures are detected, fast Ardent pneumatic fixed fire suppression systems operate using pneumatic tubing, which is pressurised with nitrogen and routed around the fire hazards. The pressurised tubing ruptures locally when exposed to the heat generated by a fire, resulting in a loss of pressure and allowing the suppression agent within the tank to be released.

2. Suppression agents are distributed The loss of pressure in the detection tubing initiates agent discharge. With Ardent direct fixed fire suppression systems, the pressurised tubing both for fire detection and agent delivery. The suppression agent is released directly to the point of ignition to provide rapid and effective suppression of the fire in small spaces.

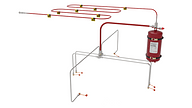

For larger, well-sealed spaces, our pneumatic indirect fixed fire suppression systems are composed of a distribution network of hoses and nozzles. Following a loss of pressure in the detection tubing, the agent is discharged through the distribution network to cover the hazard area. The nozzles are strategically located to offer optimal coverage of the protected area, suppressing fires in seconds to minimise damage.

Ardent pneumatic direct fire suppression system

Ardent pneumatic indirect fire suppression system

Choosing suppression agents for a fixed fire protection system

Fixed fire suppression systems cover a variety of hazards, which may require different suppression agents to provide the best protection for each specific fire risk:

- Clean agent. Our clean agent suppresses fires by removing heat to break the chemical reaction chain. This suppression agent leaves no residue, evaporating cleanly and removing the need for post-discharge clean up. Non-corrosive and non-conductive, it’s the ideal solution for the protection of electrical applications such as electrical panels, data centres, and transformer cabinets.

- Dry chemical agent. For applications where the use of a clean suppression agent isn't appropriate, our dry chemical suppression agent can be fitted. This agent offers excellent fire knock-down capabilities and is able to disperse widely and cover even the hardest-to-reach areas in the hazard area.